pure power. perfected.

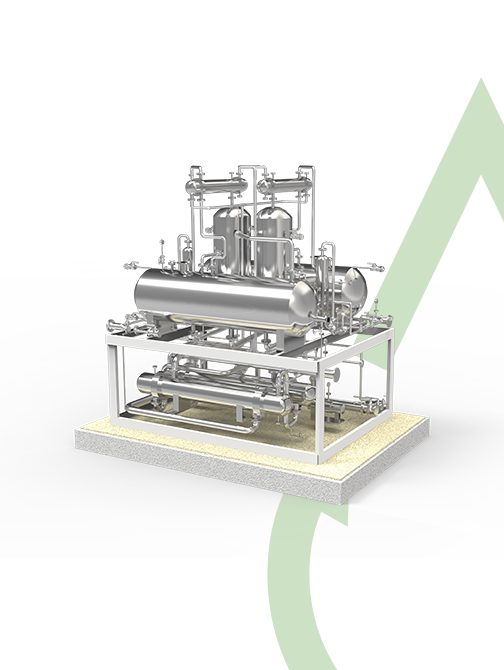

Compact design

Modular, easy integration & scalability

>99.8%

Purity of hydrogen at the outlet

>98.5%

Purity of oxygen at the outlet

<40°C

Temperature of hydrogen at the outlet

BENEFITS

Ensures long-term durability and consistent performance, minimizing maintenance requirements. This translates to lower maintenance costs and extended equipment lifespan.

FEATURES

BENEFITS

Facilitates easy integration and scalability in hydrogen production facilities, allowing for flexible installation in various environments. The compact design also saves valuable space.

FEATURES

Features a modular and compact design that can be easily expanded or reconfigured as needed. This flexibility is ideal for both small-scale and large-scale hydrogen production operations.

BENEFITS

Ensures safe and reliable operation, protecting both equipment and personnel from potential hazards. Adhering to European safety standards enhances compliance and operational safety.

FEATURES

Equipped with robust leak prevention systems and automated venting mechanisms that comply with stringent European safety regulations. These features detect and respond to leaks quickly, ensuring any issues are promptly addressed and maintaining a high level of safety.

BENEFITS

Produces high-quality hydrogen suitable for various industrial applications, enhancing product value. High purity levels are critical for applications requiring stringent purity standards.

FEATURES

Capable of achieving ultra-high purity hydrogen levels, consistently meeting and exceeding industrial standards.